TECHNOLOGIES

TECHNOLOGIESLithium-ion rechargeable hearing aids

Makichie launched the world's first lithium-ion, rechargeable hearing aids in July 2015.

The use of a lithium-ion battery realized a battery life that far exceeds that of conventional rechargeable hearing aids.

Integrating a lithium-ion battery into the ultra-compact device of a hearing aid required the redesign of every part of the electronic circuitry, housing, and control software.

It took 10 years to develop the product, which was launched in 2015, but we were able to create a hearing aid that can be easily handled by anyone and that does not require battery replacement.

Custom-made, in-the-ear hearing aids

In the past, every step of the process of making custom-made, in-the-ear hearing aids was done only by hand.

Our company installed a state-of-the-art, digitized production system more than 10 years ago.

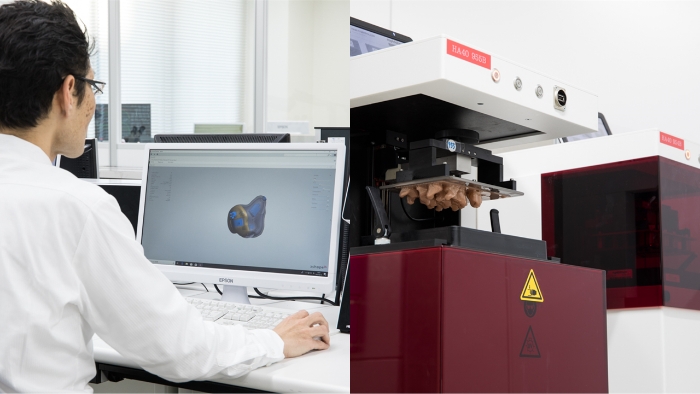

Once the ear impressions taken from the user's ears are brought to the factory, a precision laser scanner is used to convert them into 3D data.

Based on this data, an experienced operator uses CAD to design a shell that best fits the user's ear.

In this way, we are able to provide the best hearing aid for the customer’s ear.

Introduction of water-repellent, nano-coating equipment

Since hearing aids are worn on the body, there is a risk of malfunction due to perspiration.

We have been using water-repellent, nano-coating equipment for more than 10 years to reduce the risk of product failure.

The coating is very thin—only a few tens of nanometers thick—so it does not compromise the aesthetics of the product at all.

This coating protects every aspect of the product, including both the housing and the electronic circuitry inside.

In addition, the plasma treatment provides a very strong coating that does not come off easily.